When a wheel bearing is notChecked for cracks or breakage, it can cause damage to your bicycle. Cracks can lead to loss of friction and speed, or even breakage of parts.

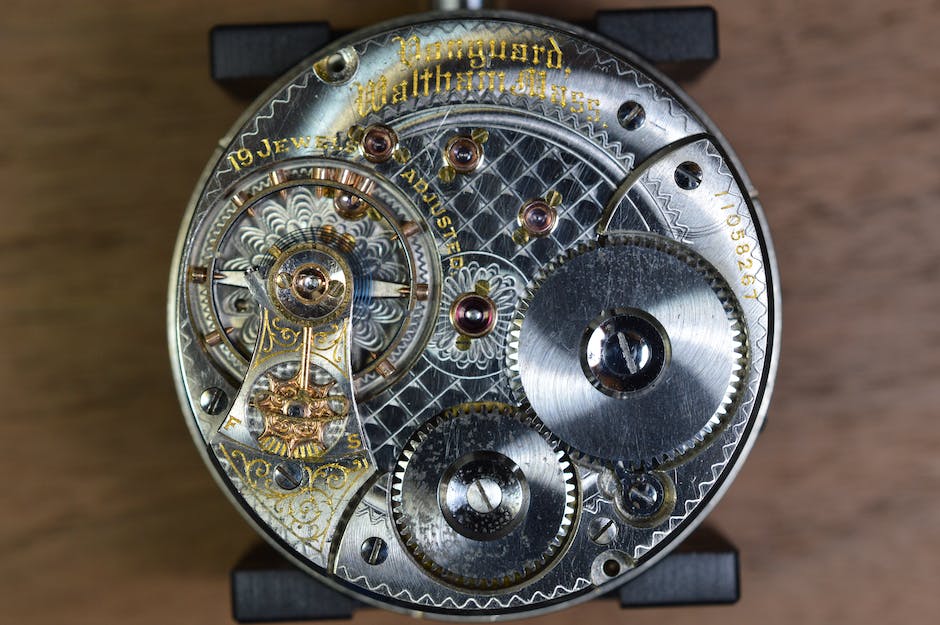

Wheel bearings are small disk-shaped structures that are pressed into a hole in the rear wheel axle. They hold the axle together and prevent it from spinning as the bicycle is ridden.

To check if a wheel has a bearing, look for a small round spot on the axle. If you see this, then your bike has a healthy one! If you see many small white spots, then your bike may have a bigger problem as some of the rings may be coming loose.

This article will talk about how to check if a wheel has a bearing or not, what type of bearing an oakum should be checked for, and how to correct an out-of-place Bearing if needed.

Contents:

Dust

When a wheel bearing seal is checking dust, it can possibly be affected by the seal. If the seal is not being checked for dust, it can become affected by debris such as sand or salt that passes through the system.

When this happens, it can no longer maintain a clean and smooth interface between the bearings and axles. This will result in poor lubrication and play in the system.

Bullet point: Play Should Be Out of Trustworthy Wheel Bearing Leads

If your trustworthy wheel bearing leads does not look out of place, then there are some things you can do to check for play. A play in the lead can come when sand or salt gets through the lead and into the system.

To check for this, you must put a small amount of product in each end of the lead and then turn them around to see if there is motion on one side or the other.

Cracks

When a wheel bearing is installed, it must be checked for cracks. A crack can allow part of the wheel to come free.

This can be scary, as you could lose your ride’s stability or you could break your wheel and put a substantial dent in your budget! Fortunately, this happens very rarely due to the frequent rotation of wheels, which locks in the bearings.

If a crack does exist, then it is recommended that a wheel be replaced with a new one half-way through this process. Due to the rotating of the old wheel to re-install the new bearing, this must be done at your shop or at an auto parts store that sells replacement parts.

The new shop owner or auto parts store owner should check the bearings for rotation before letting them go into circulation.

Ruptures

Rupture is the leading cause of stop-start riding, and unfortunately, for you, for us too! We can talk about this topic for hours, so we will keep this article short and sweet.

Rupture occurs when a wheel or wheels lose their ability to stay upright due to either a tear in the protective layer called the rubber or because the plastic casing of a wheel has worn away.

This can happen when you are mounting and dismounting your bike, or even while riding! It is one of the most important things you should check for rupture, because if your rupture has been severe, you could lose control of your bike which could result in a accident.

To prevent rupture on wheels, it is important to know what size they are. They are measured in diameter ( Dia) and they are checked for thickness ( Tint).

Lubrication

When a wheel bearing gets too hot, it can cause the seals that keep the bearings from moving around to break down the oil.

Too much oil can also result in loss of fluid and/or wheels not turning smoothly. If one of these things happens, you should check both your wheel bearings and your wheel sprockets for this reason.

Wheel bearings are a little tedious to check out, as they need to be removed by a professional wheel nut remover. However, we can do it ourselves! First, we need to determine if the bearing is old or new. If the bearing is new, then we need to purchase new seals. If the old ones broke down with use, then we can try using these new ones.

We start by placing our hand on one of the bearings and slowly lifting and moving our hand away from it until we have removed it. We then place our hand on top of the other bearing and continue pulling and moving our hands apart until we have taken off each one.

Wheel balance

When analyzing a wheel bearing seal, the first thing to look for is how it measures when mounted on the bearings.

Many seals have trouble lining up with the holes in the bearing. This requires that you buy a new seal for each hole size to correctly match up the seal with the hole. This is important as some holes require a different size than others to function properly.

Other things to look for include its thickness, how hard it is, and whether or not it has any other characteristics such as textured or grooved surfaces.

Rotate your tires regularly

When you rotate your tires, it decreases the risk of wearing down the wheel bearings on your car.

Wheel bearings are small disk-like projections that hold the tire to the wheel. When the tire is installed, it presses against these bearings, reducing the risk of them breaking.

To keep these from breaking, you must periodically install and then remove and install new tires as soon as they are mounted. This is especially important if there are winter tires on them, since snow can prevent easy installation and removal.

Driveways have a tendency to get curbs cuts, gouges, and wear over time. If those areas get bigger than the existing wheel bearing seal stops being able to seal due to poor life support. These need to be checked for wear often in order for them to maintain their seal.

Check the tire pressure daily

If your wheel bearings are not check the tire pressure daily, you can save a lot of money in wheel bearings by checking the pressure of the tires.

Wheel bearing seals are important to check every week or so to make sure they are still working. As tire pressure changes with temperature and driving condition, the seals must be checked to ensure they are still working.

This is because if one is broken, it would not be detecting enough rubber to hold the bearings together. If one is worn out, then it would not be holding up the bearing assembly, causing you problems when you drive or ride.

There are four types of seal: O-Rings, ringers, gaskets, and rachet wheels. Each type has its own requirements for Checking and Using.

When driving, do you hear a squeak or grinding sound?

If you hear a sound similar to a squeak or grinding sound when turning the wheel, then your wheel bearing seal is checking out.

This may be due to poor fitting or removal of the seal. Often times, this is due to lack of knowledge about the product and how to use it properly.

To prevent this, try using a bit more material into the sleeve of the bearing grease and make sure that it is well wrapped before applying it to the wheel. Or use a bearing grease that has been used with some kind of protective cover like plastic or rubber.

If you can hear any metal working against metal when riding, then your wheel is causing cross-threading which can lead to blowouts.