A fixed quill has a set location where the quill will rest. A sliding quill will move when the drill press is installed in a Miter or Inset Configure. This makes it easier to change thicknesses of wood without removing the drill press

When changing thicknesses of wood, the sliding quill must be removed and replaced with the new fixed qull. The old one can be placed in a scrapbook or discard pile.

Sliding quills can get kind of annoying as you have to keep moving it because of an obstructing piece. A fixed quull should always stay put while cutting as it is attached with glue or epoxy.

Contents:

What is the purpose of a quill on a drill press?

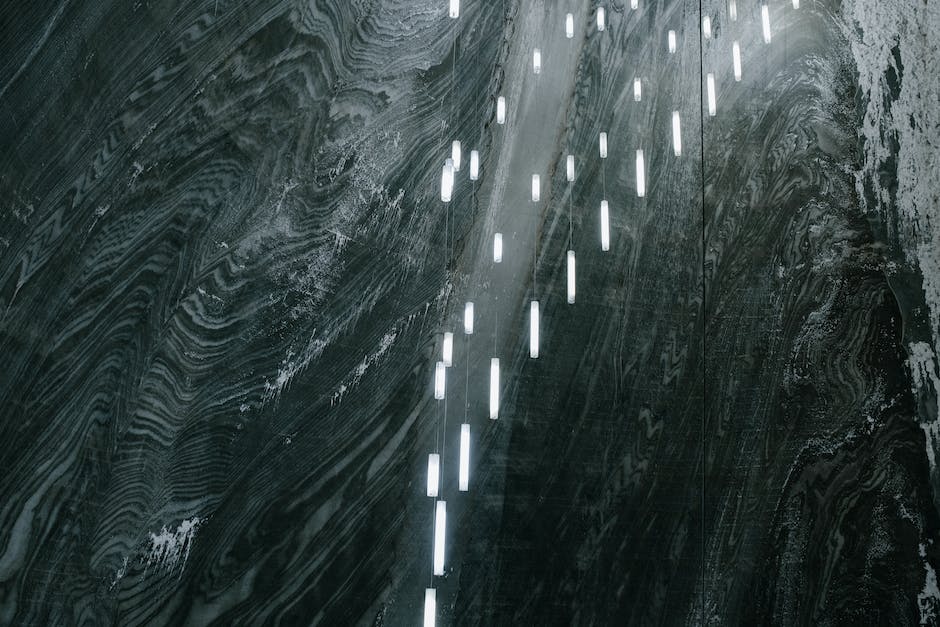

A quill on a drill press is a special feature that allows you to create indented lines in your work. Quill on drills features allow you to create tight, smooth indentations that look like the lines in the picture.

The quill on a drill press was originally developed as an alternative way to get started designing. Using a quill on a drill press allows you to start designing by creating an initial line of material followed by adding in the next line, etc.

Unfortunately, this new design method was not very popular so most manufacturers did not offer it out of respect for people who wanted to use it.

Today, there are still some designers who use the quill on a drill press but only people who know how to use it can take advantage of its benefits.

Does the quill move?

If it does not move, you are likely looking at the wrong press. Many presses have a set of parallel bars that move up and down to change the thickness of paper or wood.

If one of these points moves, it indicates a problem. Some problems can be fixed, but most professional machine shops will check all four points to make sure nothing is broken.

A broken point can be fixed, but in the case of the drill press, this may not be an issue. The press has its fourth point on a flat disk that slides into place to create a guide for driving screws. This disk can easily be replaced without needing to take off the other three components.

Carving tools like mortise and spanner kits are very useful in seeing if the drill press has enough space for your projects.

What is the difference between a fixed and sliding quill?

The term fixed quill refers to a press that has a single, permanent position for the press die.

Sliding quill presses have two sides that are interchangeable. The top side holds the block, and the lower side holds the quill.

The difference is in how the press die is held on to during manufacturing and how the quill is held on to during printing. Some presses have one or the other missing, but not both!

To print a letter A, for example, you would hold down 1st point of contact until middle of mark was reached, then release.

What type of work would you use a sliding quill for?

The sliding quill is a very popular tool to use on drill press projects. Its versatility makes it hard to stay in one place with this tool!

The sliding quill has two main uses. The first is as a speed tool. Using the sliding quill as a measuring device, you can really make quick work of small projects.

The second use for the sliding quill is as a support system. When used in conjunction with ainating materials, like wood, the sliding quill can be used as a support system for your materials.

To make the most of the sliding quill, there are some tips to take care of. First and foremost, avoid getting soap or water on it. It can cause it to break down, creating poor quality material that does not work with the press.

What type of work would you use a fixed quill for?

A fixed quill is a very precise tool that requires very little room to hold and use. You can see an example of a fixed quill in your printer’s manual!

The trick is holding the quill with one hand and turning the press with the other. This requires a lot of concentration, so do not use this tool if you are not able to hold the press in one hand, turn it with the other, and print.

There are several types of fixed quills. The most common type has a straight blade that is mounted on the press and which does not change width or thickness. The others have jagged or rounded blades that change width and thickness.

A common mistake people make when using a fixed quill is trying to turn it into a printing tabletop device. To remain a floor-leveling tool, use a gravity feeder such as an actual drill bit.

Is one type of quill better than the other?

There are two types of quill on a drill press. The first is called a straight quill. This is the equivalent of the standard sized hollow-tip drill press bullet point.

The other type of quill is the curved quilted-over one. This one can be used with either a standard or increased-size hollow-tip drill press bullet point.

Curved quills can be used with an increased-size hollow-tip Drill Press bullet point, but not a standard one. This is because the larger diameter of the curved drill press arrowhead helps it retain enough power to penetrate even hard material like granite.

Standard size curved quills can be used on either a single or double walled work bench, just make sure to have enough room for both ends of the curve.

How do you adjust the quills on your drill press?

When you need to change the quills on your drill press, you have two methods of removing them.

The first is to use a set of quill stop blocks. These are small pieces of wood that are placed underneath the top panel of the drill press and then pulled up and away.

The second is to use a loaner quill set. These are replacement quills that are provided by your hardware store or manufacturer for when the original ones fail. They can be replaced as soon as they arrive as they are store-used!

Neither of these works well on a power-driven drill press, so we recommend using loaner quills.

What steps should you take to repair your drill press quills?

Once your drill press has a quill, it is time to repair or replace the quills. A drill press quill can last weeks or months, so don’t spend money on replacing them until you have finished fixing the problem.

When cleaning your drill press quills, it is important to remove all traces of dried glue and media that may have stuck to the quill during manufacturing and processing. These can be difficult to remove without causing further damage to the quill.

To replace a lost or broken quill, first empty out any glue and media that may have accumulated on the new quill using an abrasive pad and brush.