A plasma cutter is a powerful tool that can change your welding, electrician, and carpentry industries for the better. A plasma cutter can simplify the process of cutting and cross-cutting materials like wood, paper, and metal.

Plasma cutters are typically measured in length or width and have a blade that goes in the front and a housing on the back. The blade is made of material such as acrylic or steel and is controlled by a computer system.

When you purchase one, it comes with instructions on how to use it. Most come with a demonstration DVD as well! It takes about an hour for most people to get started with their new tool so they will need time to learn how to use it properly.

Contents:

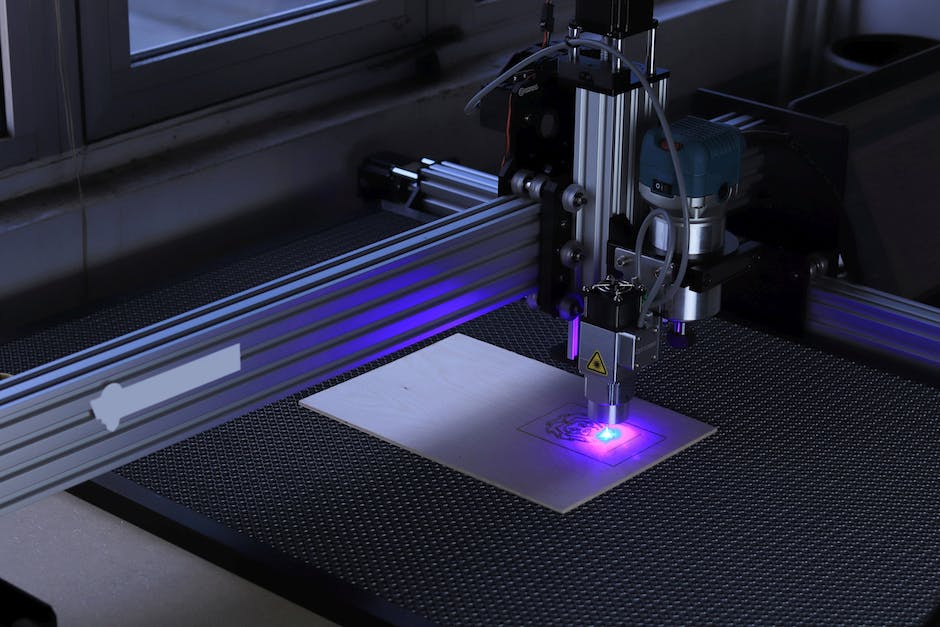

What is a CNC plasma cutter?

A CNC plasma cutter is a high-tech, computer-controlled cutting tool. A plasma cutter can be thought of as a portable, high-tech 3D printer.

Plasma cutters are typically longer and thicker than most normal desktop printers, making them harder to hide under a desk or workspace. They require special software and a computer to operate, making it more difficult to locate one in an office or workplace.

But the benefit of having one is that you can create complex pieces of art or technology in just seconds. You can also use a plasma cutter to create pilot carves for new furniture, or quick fix jobs like this: fixing some cracks in a freshly painted wall.

Most cubicfoots offer self-leveling capabilities which make it easy to correct for poor cutting skills. Once trained, the job takes about five minutes per person.

Components of a CNC plasma cutter

A plasma cutter is a more advanced tool than a stereolithographic printer. Instead of using solid materials to build models, like a 3D printer, the plasma cutter uses electricity to fire hot electrons into materials.

This creates dramatic and intricate structures that can be shape-shift and rearranged as you change voltage and current. This feature, called radio-frequency transformation or RF transform, is what makes the plasma cutter so impressive.

It can cut through very hard substances, like stainless steel or titanium. Because it does not require sanding or routing, the cut quality is better than with a 3D printer.

A common use for a plasma cutter is in cutting parts for drone builds.

Power of a CNC plasma cutter

A plasma cutter is a powerful tool that can make very fine cuts. A good one can make around twenty complete cuts in a minute!

A cutting zone is created by the plasma device and then you throw your arms up and let them work. This allows them to create very powerful cuts that last a long time.

Many people use their plasma cutters for small repairs andstencils, but there are many uses for this tool as well.

For example, you could print some replacement printed parts or fill in some holes on an item when using a plasma cutter.

Control of a CNC plasma cutter

A plasma cutter is a very special type of laser cutter. A plasma cutter can be used for all types of cutting, including computer-controlled cutting.

Most common term isCutRite! TheCutRite! It can do all kinds of cutting, from simple to complex. Most cutters do not have a license to use them on material that does not require a high degree of precision.

However, most schools and colleges have a license for the students to use their cuttings as research material! That is what this article is about!

To learn more about the differences between an ordinary laser cutter and a CNC plasma cutter, try reading this bullet point again.

Comparison between gas and electric cutters

Gas cutters offer a more relaxing experience than electric cutters. Because the gas cutter is working against the air instead of electric power, it offers reduced stress on the user.

However, due to the fact that you are cutting through electricity, you will need to pay a little extra for that privilege. Because there is no vacuum needed, this will mean there will be more outlets to use!

There are also concerns about eye protection because of the bright light that is used to cuts. If you are not comfortable with that, then gas cutters may be better suited for you.

Because of the reduced pressure in which the cutter works in, there may be less knowledge required in order to use a cutter. This can cause people with less experience to get confused and upset which is worse.

What are the benefits of a C NC plasma cutter?

A plasma cutter is a relatively new tool in the office, school, and home. There are very few people who have a plasma cutter- you are a cutie!

It is a powerful tool that can make small pieces of wood, paper, or plastic stack and stick together without breaking. This ability to stack items makes it very valuable.

Using a plasma cutter allows you to cut metal, wood, and plastic. The best ones can cut up to 1/4 in.!

You can find one for around $100– $150 is a reasonable price tag for most people. The best ones can cost more than your average person would spend on one!

We will not talk about the dangers of using one, but instead give some tips on how to use one safely.

Who should buy this equipment?

A plasma cutter is a very important piece of equipment to buy. It can make a huge difference in the quality of your craft projects.

If you are looking into developing your own projects, then a plasma cutter is definitely a piece ofcraft equipment. These cutting tools are generally built for cutting hard materials, like wood or metal.

However, they also can be used for cutting softer materials like plastic and foam. The right person should use it at the right time, though!

When looking into how to use a plasma cutter, you need to know what materials it is supposed to cut. This depends on whether you want it as an entry-level tool or if you have more advanced skills.

The main differences between the two are how much knowledge one has on the field and how quickly one gets used to them.

What are the drawbacks of a CNC plasma cutter?

There are some downsides to the majority of plasma cutters on the market. Some of these changes can make a difference in how fast you can cut!

Some cuts cannot be done with a plasma cutter, making it not the right tool for every project. These include precision cutting, such as when preparing a piece of wood or metal for a craft or construction project.

Another issue is heat quality. Some cuts may require less heat than others due to heat quality issues. If you need more control over the heat, then an air cooled system is better suited than a commercial grade one.

Lastly, comfort is an issue when working in direct sun for long periods of time. A plasma cutter requires special protection from overheating and damage due to overheat or break-down.